765*525*690mm Mechanical Shaker Table For Components Testing With Damping Airbag

765*525*690mm Mechanical Shaker Table For Components Testing With Damping Airbag

Application

Mechanical vibration test machine applies to electronic products,

components, module, mechanical and electrical products, instruments

and meters and other transportation vibration simulation test. It

meets the standards of GB, UL, IEC vibration test and reliability

test.

Specifications

| Model | RV3000 |

| Table Size (L*W) | 600*500mm |

| Frequency Range | 5-50Hz |

| Amplitude Range(mmp-p) | 0-3 |

| Acceleration Range | 0-11G |

| Max.Payload(kg) | 130 |

| Control Interface | (compatible interface)IBM PC Serial port Rs232 9P/USB port |

| Test Method | Fixed frequency.sweep frequency(linear/logarithm),multi-stage random |

| Waveform | Sine Wave |

| Vibration Direction | Vertical |

| Power Supply | AC 220V/50Hz |

| Size(mm) | 765*525*690 |

| Weight(kg) | 250 |

Features

1, Using centrifugal excitation method, low mechanical noise.

2, Using synchronous reverse movement, excellent table evenness.

3, Stepless amplitude adjustment, meet different product test

requirements.

4, Use-friendly operation control interface.

5, Fixed with shock absorption bags without special foundation.

FAQ

Are your company a trading one or a factory ?

Directly factory, more than 15 years focusing on test instruments field, 6 years exporting experience.

How do you attach the hardware you’re testing to your shaker?

By means of a fixture, usually aluminum or magnesium for lightness coupled with rigidity. They can be cast, or smaller fixtures machined from solid stock. Most fixtures are welded.

How do you control shakers?

If we’re looking for resonances in the product we’re testing, we command the shaker to shake the product at one frequency at a time but to vary that test frequency, to sweep it over a range of frequencies.But more realistically, we command the shaker to vibrate randomly and to excite all the resonances simultaneously.Control commands go into the keyboard of a specially-programmed computer.

What are those resonances?Are they bad?

Have you ever noticed the steering wheel moving with rather large displacement amplitude, larger than the input to the column? That magnification is called resonance. Possibly it annoys you. There’s a slight chance that in a few years that whipping of the steering column might cause bending fatigue failure.When we shake an automotive or ship or land vehicle instrument, we're looking for, for example, portions of printed wiring boards (PWBs) responding with greater motion than we're inputting. That flexing may damage PWB wiring, it may damage the attached components, and it will damage the soldered connections between components and the PWB.

| Service | |

| Pre-Sales Service 1)Technical consultation: test method, laboratory planning and suggestion. 2)Equipment selection: selection scheme, FAQ. 3)Product testing scheme. 4)Customer communication and progress report. | After-Sales Service 1)Technical training: operation of equipment, daily maintenance, common fault diagnosis and troubleshooting. 2)Scheduled on-site service: Detection of problem as soon as possible in order to eliminate equipment and anthropogenic hazards. This is to ensure long term and stable equipment operation as well as delivery of latest technical information. 3)Technical support: special paid services are provided according to customer’s needs. |

Product Show

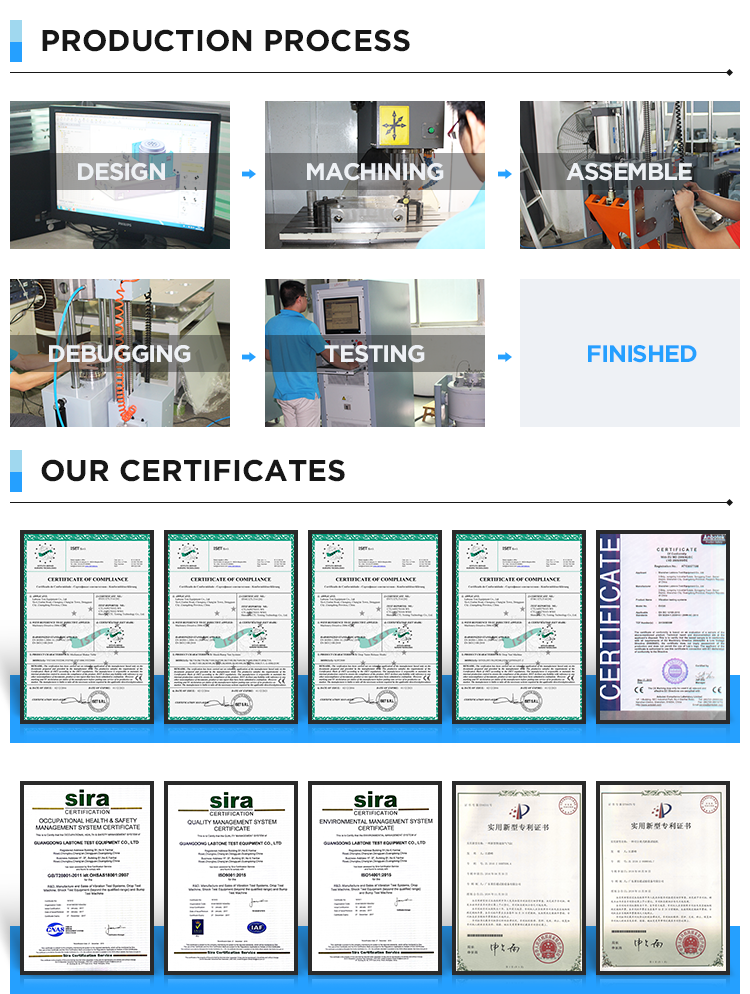

Labtone Test Equipment Co., Ltd

Labtone Test Equipment Co., Ltd. is a +20 year China manufacture of reliable, cost-effective equipments . Our superior products mainly include: Vibration Test Systems, Shock Test Systems, Bump Test Machine, Drop Tester, Transportation Simulators, Combined Environmental Test Chambers.

Labtone started business in 2002 in a plant located in Shenzhen and moved to our new, expand 6,000 square meter facility in Donguan, GuangDong in 2015.Today, Our products are found around the world in electronics, automotive,automotive,aerospace,telecommunication, optoeletronics instrument and industrial machinery applications. Our experience, and commitment to new product development, has resulted in products that are easy to use,accurate and designed for decades of service

Labtone products carry a one-year(12months) Warranty and are available direct from our factory in Dongguan, China. We provide comprehensive factory service and support,technical literature, manuals and guides as well as having a qualified staff of experts to help solve your application issues.

We sincerely invite you to visit our factory.